Key Takeaways

- Revolutionizing Manufacturing: AI is transforming the manufacturing sector by improving efficiency, reducing costs, and enhancing innovation through data-driven decision-making.

- Predictive Maintenance: Utilizing AI for predictive maintenance helps monitor equipment health and predict failures before they lead to costly downtimes, increasing operational efficiency.

- Enhanced Quality Control: AI-powered quality control systems ensure high standards by automatically detecting defects and facilitating continuous improvement in production processes.

- Supply Chain Optimization: AI enhances supply chain management by accurately forecasting demand, optimizing inventory levels, and streamlining logistics, leading to reduced costs and improved responsiveness.

- Robotics and Automation: AI-driven robotics enable flexible manufacturing operations, adapting to changing demands while collaborating with human workers to boost productivity and safety.

- Addressing Challenges: Companies must navigate challenges such as data privacy, implementation costs, and workforce implications to successfully integrate AI into their manufacturing processes.

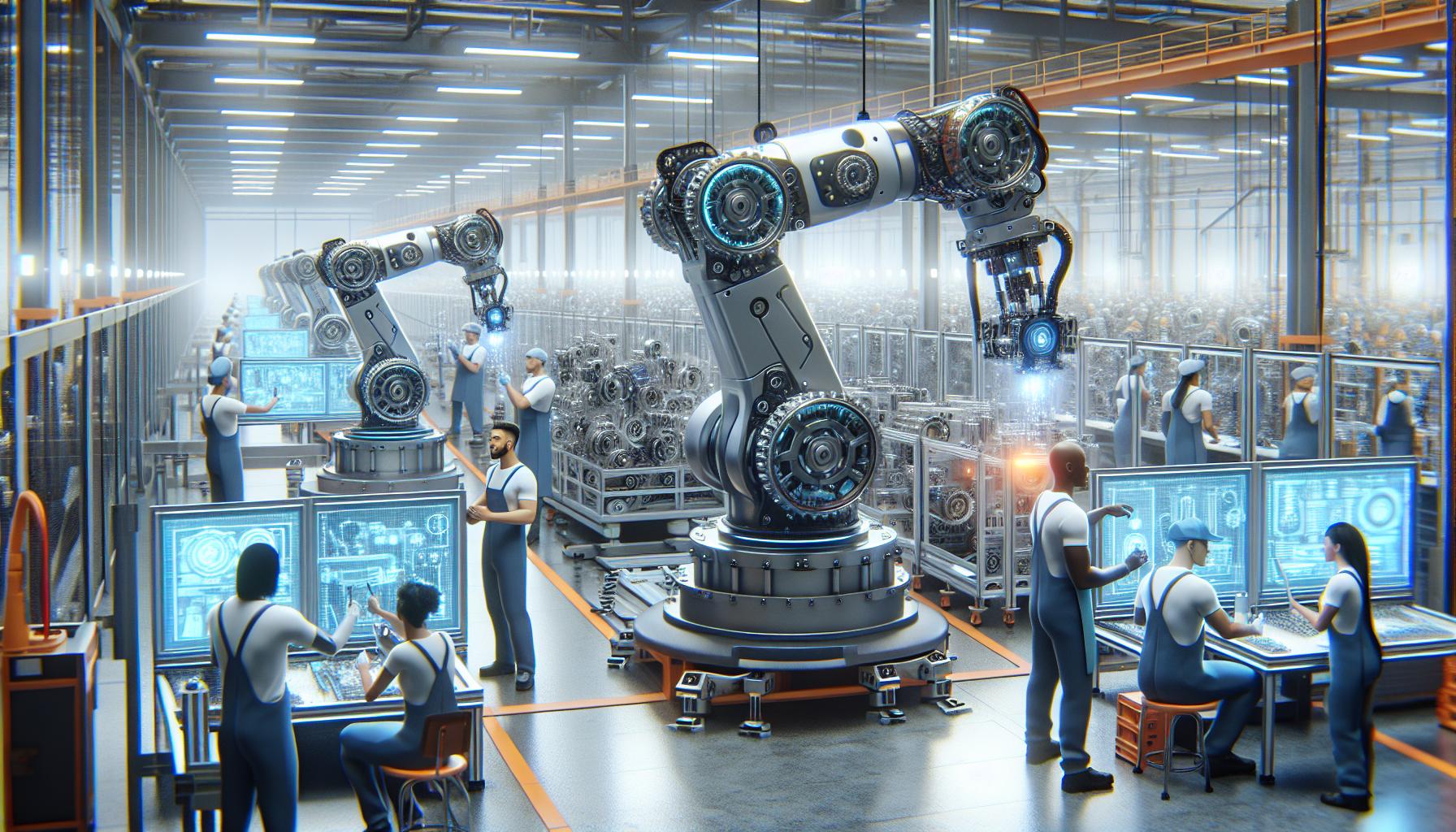

Artificial intelligence is revolutionizing the manufacturing sector, driving efficiency and innovation like never before. As companies face increasing pressure to reduce costs and improve productivity, AI technologies are stepping in to streamline processes, enhance quality control, and optimize supply chains.

From predictive maintenance to smart robotics, AI is transforming how manufacturers operate, enabling them to stay competitive in a rapidly evolving marketplace. This shift not only boosts operational effectiveness but also paves the way for new business models and opportunities. Embracing AI in manufacturing is no longer just an option; it’s becoming a necessity for those looking to thrive in the future of industry.

Artificial Intelligence In Manufacturing

Artificial intelligence (AI) plays a pivotal role in modern manufacturing, driving significant advancements and efficiencies. AI technologies enable manufacturers to automate repetitive tasks, reducing labor costs while enhancing productivity. With AI, companies analyze vast amounts of data to make informed decisions, allowing for real-time adjustments in production processes.

AI-powered quality control systems utilize machine vision to detect defects with precision. Implementing these systems minimizes errors and maintains product standards. Smart robotics, equipped with AI algorithms, can adapt to changing environments, increasing flexibility on the assembly line.

Predictive maintenance, facilitated by AI, allows manufacturers to monitor equipment health proactively. Data from sensors predicts failures before they occur, reducing downtime and maintenance costs. This approach extends the lifespan of machinery and enhances overall operational efficiency.

Supply chain optimization is another crucial application of AI in manufacturing. AI models can forecast demand, allowing manufacturers to adjust inventory levels accurately. By streamlining logistics and reducing waste, companies enhance their responsiveness to market changes.

AI also supports innovation in product design and development. Machine learning algorithms analyze customer feedback and market trends, guiding the creation of products that meet consumer demands effectively. This agility fosters a competitive edge, essential in today’s fast-paced market.

Overall, the integration of AI in manufacturing signifies a shift toward smarter, data-driven operations that enhance competitiveness, efficiency, and adaptability.

Key Benefits Of Artificial Intelligence In Manufacturing

Artificial intelligence (AI) brings significant advantages to the manufacturing sector. Key benefits include improved efficiency, cost reduction, and enhanced quality control.

Improved Efficiency

AI technologies streamline manufacturing processes, enabling companies to increase operational speed. Automated systems handle repetitive tasks effectively, reducing cycle times. AI can analyze production data in real-time, allowing immediate adjustments to workflows. Smart robotics contribute to flexibility by accommodating diverse tasks and adapting to changes in production demands. These improvements result in higher throughput and reduced lead times.

Cost Reduction

Implementing AI leads to substantial cost savings for manufacturers. Automation decreases the reliance on human labor, minimizing wage expenses. Predictive maintenance powered by AI prevents equipment failures, mitigating costly downtimes and unscheduled repairs. Additionally, AI algorithms optimize inventory levels, reducing excess stock and lowering storage costs. These strategies together enhance overall financial performance for companies.

Enhanced Quality Control

AI significantly elevates quality control standards in manufacturing. Machine vision systems automatically identify defects during production, ensuring only high-quality products progress through the assembly line. Algorithms analyze quality data to identify patterns and root causes of defects, facilitating continuous improvement. By minimizing errors and maintaining product standards, companies foster greater customer satisfaction and loyalty.

Applications Of Artificial Intelligence In Manufacturing

AI technologies significantly enhance various facets of manufacturing, streamlining processes and boosting overall productivity. The following subsections outline key applications of AI within this sector.

Predictive Maintenance

Predictive maintenance employs AI algorithms to assess equipment condition continuously. Manufacturers can monitor real-time data from machines to detect anomalies, predicting failures before they occur. This proactive approach minimizes unplanned downtime by facilitating scheduled maintenance. By extending equipment lifespan and ensuring consistent performance, companies reduce costs associated with repairs and operational disruptions.

Supply Chain Optimization

AI optimizes supply chains by analyzing historical data and market trends. Machine learning models forecast demand, allowing for efficient inventory management and timely responses to fluctuations. With AI, manufacturers can enhance logistics by automating ordering processes, reducing lead times, and maintaining optimal stock levels. This results in decreased excess inventory costs and improved responsiveness to consumer needs.

Robotics And Automation

Robotics empowered by AI significantly transforms manufacturing operations. Intelligent robots adapt to variable production demands by altering their tasks efficiently. These robots not only handle repetitive tasks but also collaborate with human workers, enhancing workplace safety and flexibility. Incorporating AI into robotics enables manufacturers to achieve high levels of precision, reduce product defects, and accelerate production cycles.

Challenges And Considerations

Adopting artificial intelligence in manufacturing presents several challenges and considerations that companies must address to maximize benefits and mitigate risks.

Data Privacy And Security

Data privacy and security concerns arise as manufacturers collect and analyze large volumes of sensitive information. Companies must implement robust cybersecurity measures to protect against cyberattacks and data breaches. Ensuring compliance with regulations, such as the General Data Protection Regulation (GDPR), is crucial for safeguarding customer and operational data. Regular security audits and updated software systems help maintain a secure environment and build trust with stakeholders.

Implementation Costs

Implementation costs can be a significant barrier to AI adoption in manufacturing. Initial investments in technology infrastructure, software, and employee training can overwhelm small to medium enterprises. Companies must evaluate potential return on investment (ROI) carefully by considering long-term savings from increased efficiency and reduced operational costs. Developing a phased approach to implementation can mitigate financial strain and facilitate smoother integration of AI tools into existing processes.

Workforce Implications

Workforce implications related to AI integration pose essential considerations for manufacturers. While automation enhances productivity, it may displace specific job functions, leading to employee concerns about job security. Companies should prioritize reskilling and upskilling initiatives to prepare workers for new roles focused on overseeing automated systems and data analysis. Fostering a culture of adaptability ensures a smoother transition while promoting employee engagement and satisfaction.

The Integration of Artificial Intelligence

The integration of artificial intelligence in manufacturing marks a significant evolution in the industry. Companies that embrace these technologies not only enhance their operational efficiency but also position themselves for future growth. By automating processes and leveraging data analytics, manufacturers can achieve higher productivity and better quality control.

As AI continues to shape the landscape, staying ahead of the curve is essential. Organizations must navigate challenges like data security and workforce adaptation while reaping the benefits of innovation. Prioritizing reskilling initiatives will ensure that employees are equipped for the new demands of a tech-driven environment. Embracing AI isn’t just a trend; it’s a strategic move toward a more competitive and resilient manufacturing sector.